Eagle TX 130

Textile Industrial Series

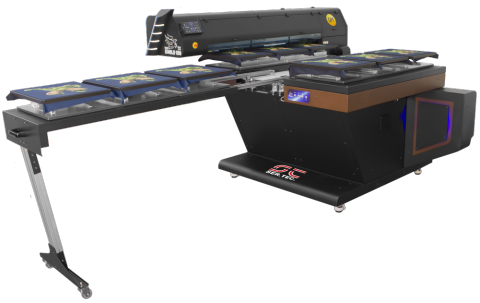

The Eagle TX series is perfect for printing every item of clothing and is made up of several models, Eagle TX 70 and Eagle TX 130 which are different for the print width and the new Eagle TX S series, which allows a greater production thanks to the possibility of mounting from 2 to 4 configurable heads. Finally, for the large format, the Eagle TX XL, with the possibility of a print table with customizable length that allows you to print an even wider surface.

Like the other Eagle printers Eagle TX are provided with white recirculation system with pressured colours, height sensors and brushless engines with encoder sensors.

The supplied equipment includes the WhiteRIP dedicated software, with specific functions realized purposely for Textile Printing.

Remote printer management via tablet allows you to view printer status and perform management operations even without being physically close to the printer.

Eagle TX 130 is characterized by a large print area that can be divided into tables of various sizes according to customer requirements, up to 18 A4 platens.

The central platens have been equipped with a sliding system that allows them to be extracted from the machine while the printer is in operation to be able to unload and reload them, eliminating waiting times and cycle stops.

The platens can be easily removed to install an optional 130x150cm printing table in a few minutes to print pre-cut and fabrics in general.

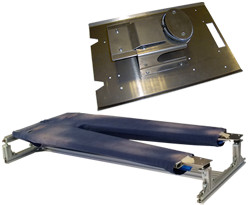

Custom platen

The equipment include standard size platen, but if you need we can provide platen of non-standard size and to print the full table. We have also platen for jeans and caps to let you print on any garment you want.

Open ink system

The under pressure ink system avoid the formation of air bubble on the circuit, the white ink is also on constant recirculation to avoid the sedimentation. The result is a global cost reduction with reduced maintenance downtime and less print head cleaning required.

New generation Print Heads

The new print heads have a better performance, they last longer, thanks to the mirror treatment to prevent the deposit of color and clogging of the print nozzles.

Optional double print head

Thanks to the proprietary multihead technology it is possible to manage 2 independent printheads, increasing the printing speed without affecting the quality.

Material thickness up to 250mm

One of the most important features is the ability to work with a variable thickness up to 250 mm. The machine automatically detects the height of the object and sets all parameters to achieve optimum print quality.

Remote management via tablet

Eagle printers of new generations can be controlled remotely via tablet. This allow the operator to perform the normal management operations and always have the printer status available.

Dedicated software RIP

WhiteRIP is the professional printing software developed by EV Network s.r.l that has specific function for textile and industrial printing to increase output and reduce preparation time like inline printing and template management.

| Technical details | Eagle TX 130 | |

|---|---|---|

| Printing Technology | piezo drop-on-demand, multilevel inkjet tecnology (3-6 picoliters) | |

| Print heads | 1 or 2 | |

| Resolution | Min | 360 |

| Max | 1440 | |

| Maximum Printable Area | Width | 1300mm |

| Length | 1500mm | |

| Maximum Material Thickness | 250 mm | |

| Inks | Waterbase | |

| Available color configurations | CMYK CMYK (Double four-color process) CMYK+W ( four-color process + White ) 2xCMYK + 8xWhite (only with double printhead option) |

|

| Power Supply | AC 100 a 240V +-10% 50/60Hz | |

| Power Consumption | 600W | |

| Operating Environment | 20-25°C Humidity 35-80% without condensation | |

| Included Software RIP | WhiteRIP 7 | |

With Inline printing function of WhiteRIP it's possible to print white and color layer together with the same quality, color tone and brightness of the two pass printing but twicing the speed.

IRS is an innovative system that allows your machine to improve performance through a constant recirculation of white ink that prevents creation of sediment and clogging of the nozzles in the head.

Thanks to sincroprint function you will be able to print the white base and colours together in a single print. This will eliminate the time for the second print halving the time and increasing the output!

The PHPC system produces uniform prints and assures that the head installed in the printer is protected from strikes by constantly checking the position.

Line of dedicated inks, divided into different lines, UV Led, Hybrid and Water base. SER.TEC. and DPI DG Printing recommend its use, as they are specifically for their own printers.