Ser.Tec. offers a complete line of products for printing on glass, both with both digital and screen printing technology.

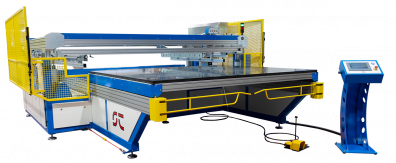

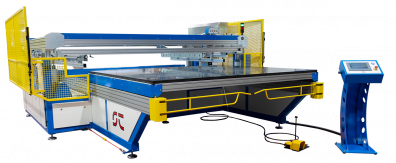

The screen printing machine S3P for printing glass sheets up to 200x300cm is equipped with solutions dedicated to glass printing such as the suction and blowing print table for easy handling and locking of the sheets and an electric positioning pin to simplify the positioning of the glass.

Setup times are extremely reduced thanks to the pneumatic lock of the screen, squeegee and scraper which guarantee maximum repeatability, avoiding even the slightest movement.

To optimize the printing time the length of the print movement can be adjusted from the panel.

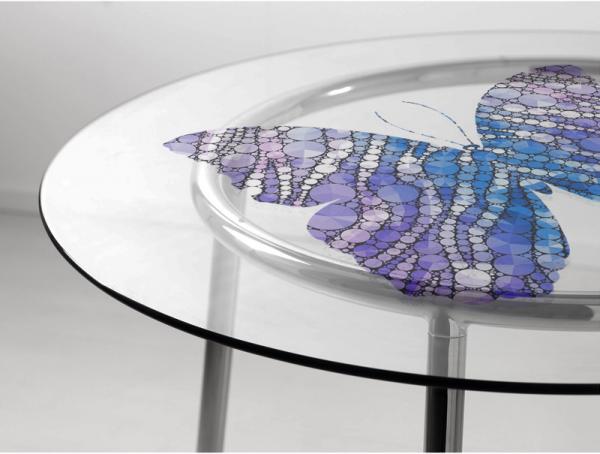

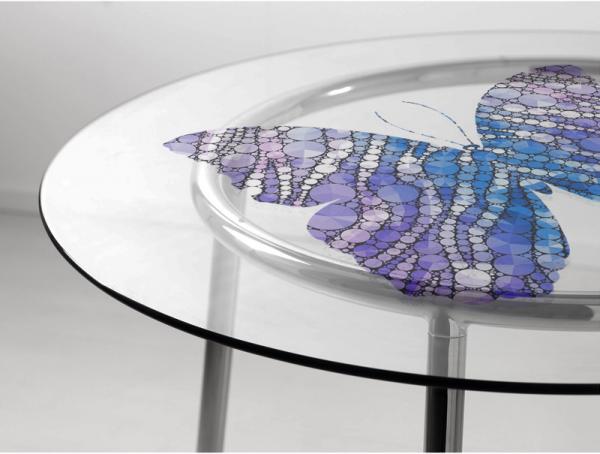

The digital printing solutions are based on the Hybrid technology developed by Ser.Tec. with specific inks for glass printing and halogen lamp mounted on the print heads for fixing the print before it goes into the oven, which guarantees hold and resistance.

Hybrid printers, thanks to their technology and specific inks, allow to obtain photographic quality prints with excellent hold and resistance even on a difficult material such as glass.

The screen printing machine S3P for printing glass sheets up to 200x300cm is equipped with solutions dedicated to glass printing such as the suction and blowing print table for easy handling and locking of the sheets and an electric positioning pin to simplify the positioning of the glass.

Setup times are extremely reduced thanks to the pneumatic lock of the screen, squeegee and scraper which guarantee maximum repeatability, avoiding even the slightest movement.

To optimize the printing time the length of the print movement can be adjusted from the panel.

The digital printing solutions are based on the Hybrid technology developed by Ser.Tec. with specific inks for glass printing and halogen lamp mounted on the print heads for fixing the print before it goes into the oven, which guarantees hold and resistance.

Hybrid printers, thanks to their technology and specific inks, allow to obtain photographic quality prints with excellent hold and resistance even on a difficult material such as glass.

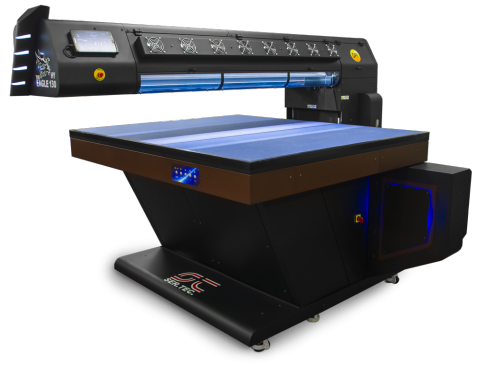

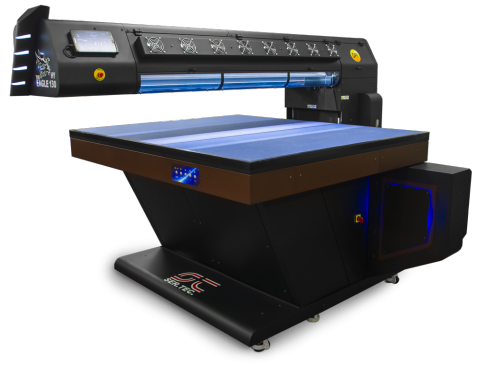

The digital printing solutions include printers from the Eagle Series in the Hybrid version.

The printing table is vacuumed and blowing and thanks to the wing design it is open on 3 sides, this further facilitates the positioning and handling of the glass sheets.

Eagle Hybrid is available in different sizes: Eagle Hybrid 70 (70x150cm), Eagle Hybrid 130 (130x150cm) and Eagle XL with a maximum print area of 130x500cm.

For larger print formats Ser.Tec. also offers Condor and Atom Hybrid.

Condor Hybrid is equipped with 2 print heads and a customizable print area from 160x250cm to 160x500cm.

The Atom digital printer mounts Ricoh Gen 5 print heads b> and is available with a print area of 250x130cm or 200x300cm.

Both Condor Hybrid and Atom are equipped with halogen lamps on the side of the head and a vacuum and blowing printing table.

The digital printing solutions include printers from the Eagle Series in the Hybrid version.

The printing table is vacuumed and blowing and thanks to the wing design it is open on 3 sides, this further facilitates the positioning and handling of the glass sheets.

Eagle Hybrid is available in different sizes: Eagle Hybrid 70 (70x150cm), Eagle Hybrid 130 (130x150cm) and Eagle XL with a maximum print area of 130x500cm.

For larger print formats Ser.Tec. also offers Condor and Atom Hybrid.

Condor Hybrid is equipped with 2 print heads and a customizable print area from 160x250cm to 160x500cm.

The Atom digital printer mounts Ricoh Gen 5 print heads b> and is available with a print area of 250x130cm or 200x300cm.

Both Condor Hybrid and Atom are equipped with halogen lamps on the side of the head and a vacuum and blowing printing table.

For the complete curing of the print on glass, a passage in the oven is necessary, and Ser.Tec. proposes the Ser.Air Glass oven a modular oven with hot and cold air spans. The heating takes place through adjustable radiant panels that can bring the material temperature up to 200° C. The width up to 250cm and the sturdy handling rollers make it suitable also for large size and weight slabs. Ser.Tec. printers can also be inserted in automatic production lines , such as the line made with Eagle Hy 70 Line . This printing line consists precisely of an Eagle Hy 70 Line printer with belt for material handling, pre-heaters to heat the glass before printing and an in-line oven for the final drying of the glass . The sensors for the automatic detection of the incoming materials and their length, allow to automatically adjust the start and length of the print. The modular constructions of the Ser.Tec. printers allow to insert them in existing production lines and to customize them according to the customer's production needs.

The screen printing machine S3P for printing glass sheets up to 200x300cm is equipped with solutions dedicated to glass printing such as the suction and blowing print table for easy handling and locking of the sheets and an electric positioning pin to simplify the positioning of the glass.

Setup times are extremely reduced thanks to the pneumatic lock of the screen, squeegee and scraper which guarantee maximum repeatability, avoiding even the slightest movement.

To optimize the printing time the length of the print movement can be adjusted from the panel.

The digital printing solutions are based on the Hybrid technology developed by Ser.Tec. with specific inks for glass printing and halogen lamp mounted on the print heads for fixing the print before it goes into the oven, which guarantees hold and resistance.

Hybrid printers, thanks to their technology and specific inks, allow to obtain photographic quality prints with excellent hold and resistance even on a difficult material such as glass.

The screen printing machine S3P for printing glass sheets up to 200x300cm is equipped with solutions dedicated to glass printing such as the suction and blowing print table for easy handling and locking of the sheets and an electric positioning pin to simplify the positioning of the glass.

Setup times are extremely reduced thanks to the pneumatic lock of the screen, squeegee and scraper which guarantee maximum repeatability, avoiding even the slightest movement.

To optimize the printing time the length of the print movement can be adjusted from the panel.

The digital printing solutions are based on the Hybrid technology developed by Ser.Tec. with specific inks for glass printing and halogen lamp mounted on the print heads for fixing the print before it goes into the oven, which guarantees hold and resistance.

Hybrid printers, thanks to their technology and specific inks, allow to obtain photographic quality prints with excellent hold and resistance even on a difficult material such as glass.

The digital printing solutions include printers from the Eagle Series in the Hybrid version.

The printing table is vacuumed and blowing and thanks to the wing design it is open on 3 sides, this further facilitates the positioning and handling of the glass sheets.

Eagle Hybrid is available in different sizes: Eagle Hybrid 70 (70x150cm), Eagle Hybrid 130 (130x150cm) and Eagle XL with a maximum print area of 130x500cm.

For larger print formats Ser.Tec. also offers Condor and Atom Hybrid.

Condor Hybrid is equipped with 2 print heads and a customizable print area from 160x250cm to 160x500cm.

The Atom digital printer mounts Ricoh Gen 5 print heads b> and is available with a print area of 250x130cm or 200x300cm.

Both Condor Hybrid and Atom are equipped with halogen lamps on the side of the head and a vacuum and blowing printing table.

The digital printing solutions include printers from the Eagle Series in the Hybrid version.

The printing table is vacuumed and blowing and thanks to the wing design it is open on 3 sides, this further facilitates the positioning and handling of the glass sheets.

Eagle Hybrid is available in different sizes: Eagle Hybrid 70 (70x150cm), Eagle Hybrid 130 (130x150cm) and Eagle XL with a maximum print area of 130x500cm.

For larger print formats Ser.Tec. also offers Condor and Atom Hybrid.

Condor Hybrid is equipped with 2 print heads and a customizable print area from 160x250cm to 160x500cm.

The Atom digital printer mounts Ricoh Gen 5 print heads b> and is available with a print area of 250x130cm or 200x300cm.

Both Condor Hybrid and Atom are equipped with halogen lamps on the side of the head and a vacuum and blowing printing table.

For the complete curing of the print on glass, a passage in the oven is necessary, and Ser.Tec. proposes the Ser.Air Glass oven a modular oven with hot and cold air spans. The heating takes place through adjustable radiant panels that can bring the material temperature up to 200° C. The width up to 250cm and the sturdy handling rollers make it suitable also for large size and weight slabs. Ser.Tec. printers can also be inserted in automatic production lines , such as the line made with Eagle Hy 70 Line . This printing line consists precisely of an Eagle Hy 70 Line printer with belt for material handling, pre-heaters to heat the glass before printing and an in-line oven for the final drying of the glass . The sensors for the automatic detection of the incoming materials and their length, allow to automatically adjust the start and length of the print. The modular constructions of the Ser.Tec. printers allow to insert them in existing production lines and to customize them according to the customer's production needs.